ASME B16.36 Carbon/Stainless/Alloy Steel Threaded Orifice Forged Jack Screw Flange

Basic Info

| Model NO. | LMP-FLG |

| Manufacturing Way | Forging |

| Delivery Date | 7 - 30 Days |

| Special Flanges | Acceptable as Per Drawings |

| Transport Package | Plywood Cases/Pallets |

| Specification | 1/2′′-144′′ |

| HS Code | 7307910000 |

| Production Capacity | 10000 Tons/Month |

Product Description

| LAMAT PIPING - Flange | ||

| Name | Plate Flange,Slip-On Flange,Weld Neck Flange,Blind Flange,Socket Weld Flange,Lap Joint Flange,Thread Flange,Orifice Flange | |

| Sealing | FF,RF,RJ,RTJ,FM,MFM,TG | |

| Surface Finish | Anti-Rust Oil,Yellow Painting,Black Painting,Electrical Zinc Plated,Cold Galvanised,Hot Dipped Galvanised... | |

| Technology | Forging,Casting,Cutting,Rolling | |

| Standard | American Standard | ANSI B16.5,ASME B16.47,MSS SP-44,AWWA C207 |

| European Standard | EN1092-1 | |

| British Standard | BS4504,BS10 | |

| Italy Standard | UNI 2277-UNI2278,UNI2281-UNI2283,UNI2253-UNI2254,UNI6092-UNI6093 | |

| Germany Standard | DIN2573,DIN2576,DIN2501-DIN2503,DIN2527,DIN2627-DIN2638,DIN2565-DIN2566,DIN2641-2642 | |

| Russia Standard | GOST 12820-80,GOST 12821-80,GOST 12815,GOST 33259 | |

| South Africa Standard | SABS1123,SANS1123 | |

| Japan Standard | JIS B2220 | |

| Korea Standard | KS B1503 | |

| Australia Standard | AS2129,AS/NZ 4087,AS4331 | |

| New Zealand Standard | AS/NZ 4087 | |

| ISO Standard | ISO 7005-1 | |

| Size | 1/2"-240" // DN15-DN6000 // 15NB-6000NB | |

| Pressure | 125LBS-2500LBS // PN6-PN420 // Table-D-Table-H // T600- T4000 // 5K-40K // API 2000-15000 | |

| Wall Thickness | SCH5S,SCH10S,SCH10,SCH40S,STD,XS,XXS,SCH20,SCH30,SCH40,SCH60,SCH80,SCH160,XXS | |

| Materials | Mild/Carbon Steel | A105,Q235,A350LF2,S235JR,S275JR,ST37,ST45.8,RST37.2,C22.8,A42CP,A48CP,E24,A515 GR.60/70 |

| Stainless Steel | A182 F304(L),316(L),F321,F310S,F347H,F316Ti,317(L),F904L,1.4301,1.4307,1.4401,1.4571,254Mo | |

| Duplex Stainless Steel | UNS31803,SAF2205,UNS32205,UNS31500,UNS32750,UNS32760,1.4462,1.4410,1.4501 | |

| High Pressure Steel | A694 F42,A694 F52,A694 F60,A694 F65,A694 F70,A694 F80 | |

| Nickel Alloy | Inconel600,Inconel625,Inconel690,Incoloy800,Incoloy825,Incoloy800H,C-276,Monel400,Alloy20 | |

| Cr-Mo Alloy | A182 F11,A182 F5,A182 F22,A182 F91,A182 F9,16mo3,15Crmo | |

| Packages | Plywood Cases or Plywood Pallets or Boxes | |

| Application | Petrochemical & Gas Industry,Chemical,Machinery,Electric Power,Ship Building,Construction Water Works,Valve Industry. | |

| Advantages | High Quality + Ready Stock + Faster Delivery + Customized | |

| Brand | LMP | |

| Certificate | ISO9001,API,CE,UL/FM | |

WHO WE ARE

Lamat Piping established in 2002s,is one of China's leading piping manufacturing and exporting suppliers,specialized in qualified steel flanges, butt weld pipe fittings and malleable cast iron fittings for clients from over 60 countries and regions worldwide.

Lamat Piping is the single and independent exporting department of NPCC(National Piping Construction Cooperation),who is a group company with 5 factories located in SHANDONG and SHANXI, where the regions have very long histories in manufacturing Steel & Iron products dating back to 1990s. Lamat Piping(NPCC) aims to combine and intergrade some leading and high quality industries to become a modern and international piping supplier in the new century. Now we have more than 30 producing and machining lines with over 1000 normal workers and 80 technical employees. Our factories covers over 300,000 square meters,and has an annual output of 500,000Tons.

WHAT WE PRODUCE

Lamat Piping(NPCC) is producing flanges from 1/2'' to 144'' - Standards including ASTM B16.5, EN1092-1, BS4504, BS10, SANS1123, DIN, JIS, UNI, GOST, KS, AS, etc. Products including Plate Flanges FF/RF, Slip On Flanges FF/RF, Blind Flanges FF/RF, Welding Neck Flanges, Screwed Flange, Socketed Flanges, Lap Joint Flanges,Backing Rings Flanges,etc. Pressures includes 150LBS to 2500LBS in ASTM B16.5,PN6(T6/3/4/8) to PN100(T100/3/4/8) in EN1092-1/BS4504/BS10, T600/3/4/8 to T4000/3/4/8 in SANS1123.

Lamat Piping(NPCC) is producing butt weld fittings from 1/2'' to 144'' - Standards including ASTM B16.9, JIS B2311, EN10253, DIN, GOST...etc. Products including 45/90/180 Degree Short/Long Radius Elbow,Equal/Reducing Tee,Cross,Concentric/Eccentric Reducer,End Cap.

Lamat Piping(NPCC) is also producing malleable cast iron fittings from 1/2'' to 6'' - Standards ASME B16.3, ASME B16.14,BS EN10242,BS1256,DIN2950, BNR6943, ISO49,etc. Products including Elbow,Bend,Tee,Socket,Nipple,Bushing,Union,Cap,Plug,Back Nut.

WHAT WE SOURCE

With 30+ years constant efforts and experience,now Lamat Piping(NPCC) has become our customers' expert manufacturer and supplier for a very wide range of piping products.And today Lamat Piping is not only supplying Flanges,BW fittings & Malleable Iron Fittings produced by ourselves,but also sourcing and exporting various Pipe Fittings & Valves s from China's leading industries,including Cast Iron Valves, Ductile Iron Pipe Fitting, Stainless Steel 1,2,3PC Ball Valve, Stainless Steel 150LBS NPT/BSP Fittings, Wrought Steel Fittings,Grooved Fittings,Forged Steel Fittings,HDPE Pipes Fittings Valves,PVC Pipes Fittings Valves, Brass Valves Fittings,etc.

WHAT WE PROMISE

''BETTER QUALITY, BETTER SERVICES'' is our promise to all of our customers and ''CREATE VALUE FOR CUSTOMERS'' is our ultimate goal. Lamat Piping promises that we'll continue to put quality in the first place;besides,we will not lose our fixed-focus on the service aspect of our business,which has been,and will continue to be the foundation of our success and our future growth.

WHAT YOU CHOOSE

If you'd like to trust Lamat Piping,Lamat people will do the best to be worthy of your trust!

Manufacturing & Marking| 1.Face Machining: Flat Face(FF),Raised Face(RF),RTJ,FM,TG,etc. 2.Sealing Machining: Waterlines,Smooth Finish,Serrated Finish. 3.CNC fine finished and Marking. *Standard of the Flanges Face: The finish on the face of flange is measured as an Arithmetical Average Roughness Height(AARH). The finish is determined by the standard used. For example, ANSI B16.5 specifies face finishes within a range 125AARH-500AARH(3.2Ra to 12.5Ra). Other finishes are available on requst, for example 1.6 Ra max,1.6/3.2 Ra, 3.2/6.3Ra or 6.3/12.5Ra. Generally 3.2/6.3Ra is most common. |

| 1.Packing Protection: Each layer use plastic film to protect the surface. 2.Packing Ways: All stainless steel flanges are packed by Plywood Cases. Big size of carbon flanges are packed by Plywood Pallets. 3. Shipping Marks: Accept Customized.(Picture-3 is Lamat's general mark) 4. Marking on the products: will be Carved or Printed. Customized is accepted. |

Samples Room Show

Canton Fair & Exhibitions

FAQ

| Q0: Are you a factory or trading company? | ||

| A: We are a factory mainly producing pipe fittings & flanges. We also have cooperated factories to supply other piping products. | ||

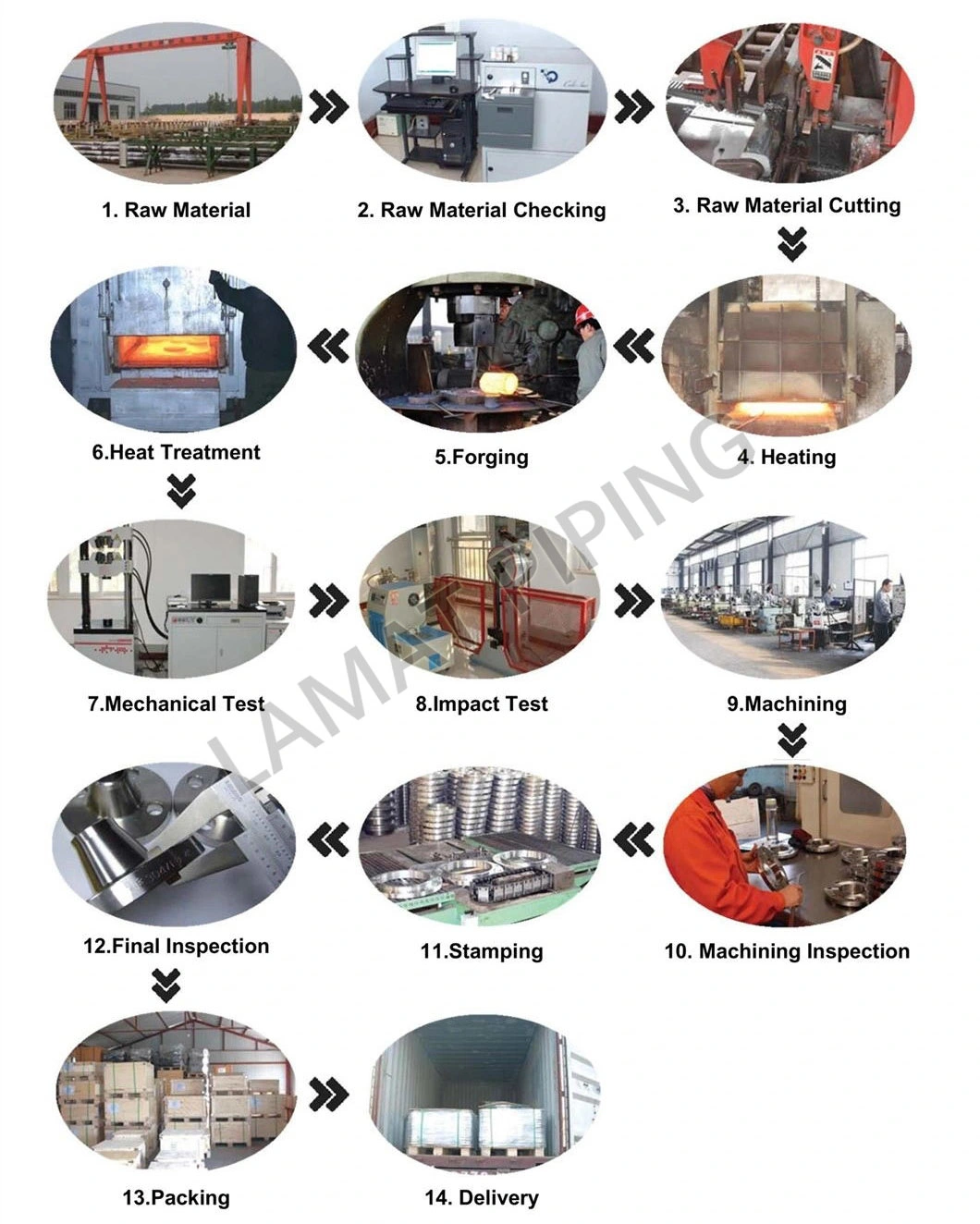

| Q1: How do your Control the Quality? | ||

| A: We have QA & QC department who will follow up all the producing process to make sure we're supplying correctly. | ||

| Q2: What Machines are you using for Manufacturing and Machining? | ||

| A: We have Forging/Stamping Machine,CNC Machine,Hole-Drilling Machine,Sandblasting Machine. All producing is in our factory except Galvanization. | ||

| Q3: Can we get Samples for Testing? | ||

| A: Yes,sapmles are supplied free of charge. | ||

| Q4: Can you accept OEM & marking our LOGO? | ||

| A: Yes,no problem if you can provide Authorization. | ||

| Q5: Can you offer Drawings & Datasheets? | ||

| A: Yes,Drawings & Datasheets will be sent for your confirmation before Bulk Production. | ||

| Q6: Can you supply MTC with EN10204 3.1/3.2 Certificate? | ||

| A: Yes,MTC will be provided after production is finished. | ||

| Q7: Can we visit your factory to inspect the goods before delivery? | ||

| A: Yes sure. Welcome to our factory,and we also accept Third Party Inspection like SGS,TUV,BV,etc. | ||

| Q8: Can you combine goods from our other suppliers to ship together? | ||

| A: Yes,we'd like to assist you to ship together to save your time and money. | ||

| Q9: How long is your Delivery Time? | ||

| A: It depends on quantity and products. It can be delivered in one week if we have Ready-Stock; if not,the General Production Time is 25 - 50 Days. | ||

| Q10: What's your Payment Terms? | ||

| A: Currently we're working with our clients under T/T,L/C,O/A,Western Union,etc. |